Low pressure molding is a relatively commonly used process in the construction of electrical systems. The technology is generally considered to stem from conventional injection molding, but with a few differences. It can be described as a cross between resin botting, as well as a classic plastic injection process. There are several uses for low pressure molding, and numerous brands offer machinery and solutions that assist with a manufacturer’s needs.

MoldMan Systems is currently a top recognized brand within this particular industry. The company offers a wide range of low pressure molding solutions that are efficient and cost-effective. We look closely at the history of low pressure molding in this post while also focusing particularly on MoldMan Systems.

The Switch To Low Pressure Molding

Injection molding used to be the standard process for creating molds in the electronics industry. Since the 1970s, however, there has been a switch to a newer technology to assist in the molding procedure, coined low pressure molding. The technology was initially used within the European market and was first seen in the automotive industry. At the time, manufacturers turned to low pressure molding as a way to develop protective coatings for various electrical parts that formed part of vehicles that were in production. The process is sometimes referred to as low pressure casting.

It was found that with low pressure molding, the parts produced were lighter, and the cycle times much faster. Furthermore, this new process also results in the production of fewer toxins, particularly when compared to the more traditional potting process. In turn, the parts that were made in the manufacturing process were also considered to be more environmentally friendly.

Following this advancement, the use of low pressure molding quickly started to spread to other industries, with the technology now being used in medical devices, consumer products, and even certain industrial machinery. Flash drives that use USB technology, control boards, and several other products also now rely on the use of low pressure molding to reduce strain on wires and provide a safer product for the end-user.

Where Does MoldMan Systems Fit Into The Picture?

While MoldMan Systems wasn’t the very first company to produce low pressure molding options for manufacturing plants, they do still play an important part in the evolution of the technology. In 1998, there were several engineers at MoldMan Systems who started to conduct research on the current methods used for this molding process at the time. There was a large focus on the processing of materials that are classified as adhesive polyamides. Following an extensive research phase, data and knowledge accumulated was used in order to lay down a foundation for the technology that was to come from the company.

By turning to the results and findings of the research phase, MoldMan Systems was able to produce more advanced low pressure molding systems in order to produce faster results, lighter parts, and a more cost-effective process that would ultimately be considered a more eco-friendly solution compared to other methods, such as potting.

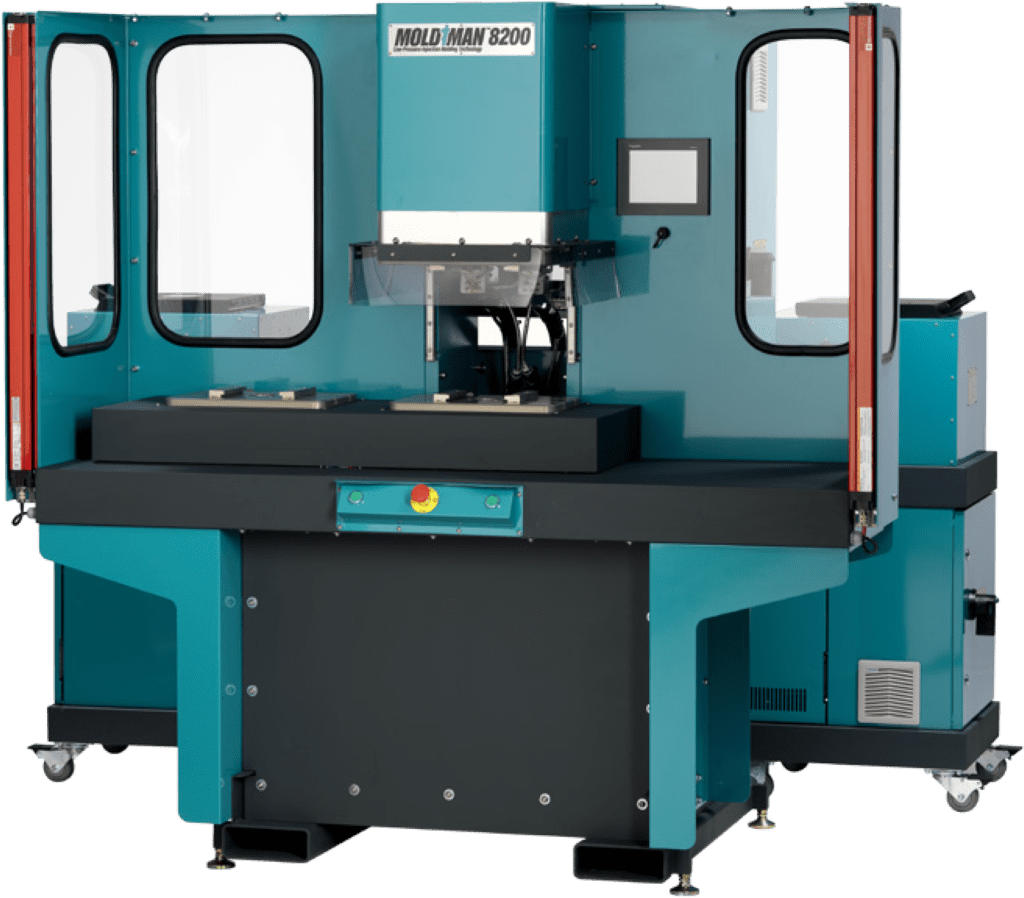

Today, MoldMan Systems is the proud owner of the company’s own patents that are held at a global level. This proves that the company has put the time and effort needed into its projects to produce systems that are more advanced. The company has also been focusing on the production of machines that reduce the footprint of low pressure molding systems in a facility.

Conclusion

While low pressure molding has been utilized since the late 1900s, MoldMan Systems have made a significant impact on this revolution within the electrical manufacturing market. MoldMan Systems now delivers a range of solutions that comes incorporated with the Melt on Demand Molding technology, driving more efficient molding solutions for projects that demand a customized result.