Cable Overmolding Assemblies for Custom and Standard Applications

High-quality component shielding with increased strength and flexibility

As with all Linear GS products, we apply the latest in technological advances to design and produce materials that meet your demands for performance in harsh environments and strive to do so from prototype to volume scale at speed.

Why cable overmolding?

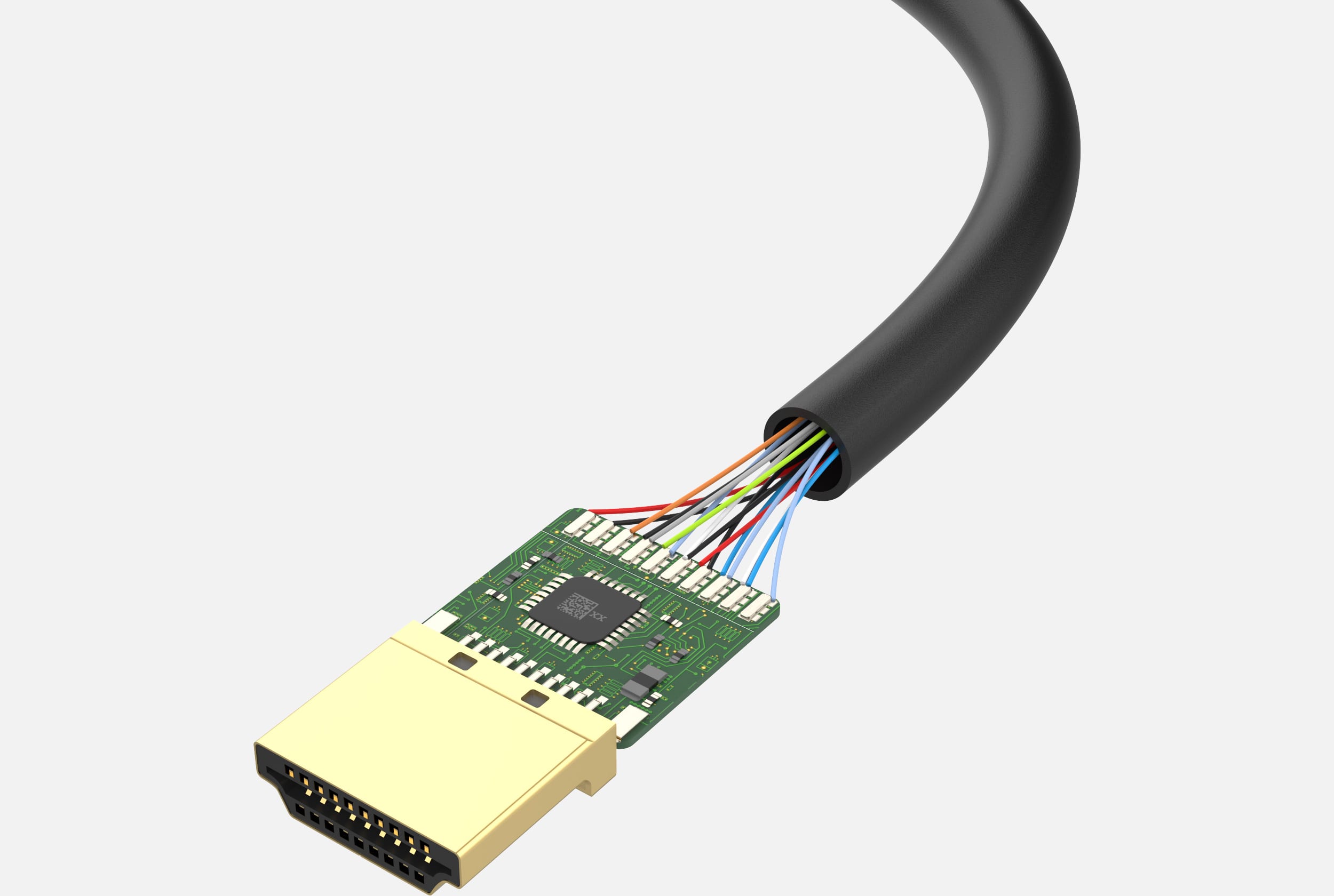

Cable overmolding shields cables and internal components and ensures high performance in even the most rugged and demanding environments. By overmolding cable assemblies, you increase flexibility, facilitate connections, provide abrasion and shock resistance, reduce clutter in engine assemblies, enable strain relief, increase water resistance, reduce human errors, and simplify installation procedures by creating a one-piece assembly with keys or color codes that can act as visual indicators to assist in pair mating.

Overmolding process is where insert molding or injection molding is used to combine wires and connectors into a single piece. In most production processes, the cable assembly is placed into a mold, then covered with thermoplastic materials by injection. Once cooled, the final product matches whatever mold was used.

LGS Overmold can suit a broad array of custom requirements for molded cable assembly, including:

Cable overmolding facilitates cost-effective and sustainable solutions for a huge variety of applications. Choose this process to:

Custom cable overmolding solutions from LGS Overmold

LGS Overmold specializes in the delivery of high-quality, on-demand cable overmolding solutions. Cable overmolding has the ability to dramatically change the appearance and function of cable assemblies and can be customized to succeed in a variety of applications, from marine and aviation to solar energy, military equipment, consumer electronics, medical equipment, and industrial/OEM applications.

We promise the quickest turnaround time in the industry and in addition to large-scale production runs can offer high-quality processing for pilot runs and low-volume production.

Not sure if cable overmolding is right for your application? Contact us now for a free low-pressure cable overmolding suitability analysis.