Electronics Overmolding For Demanding Applications

Secure Your Most Important Components

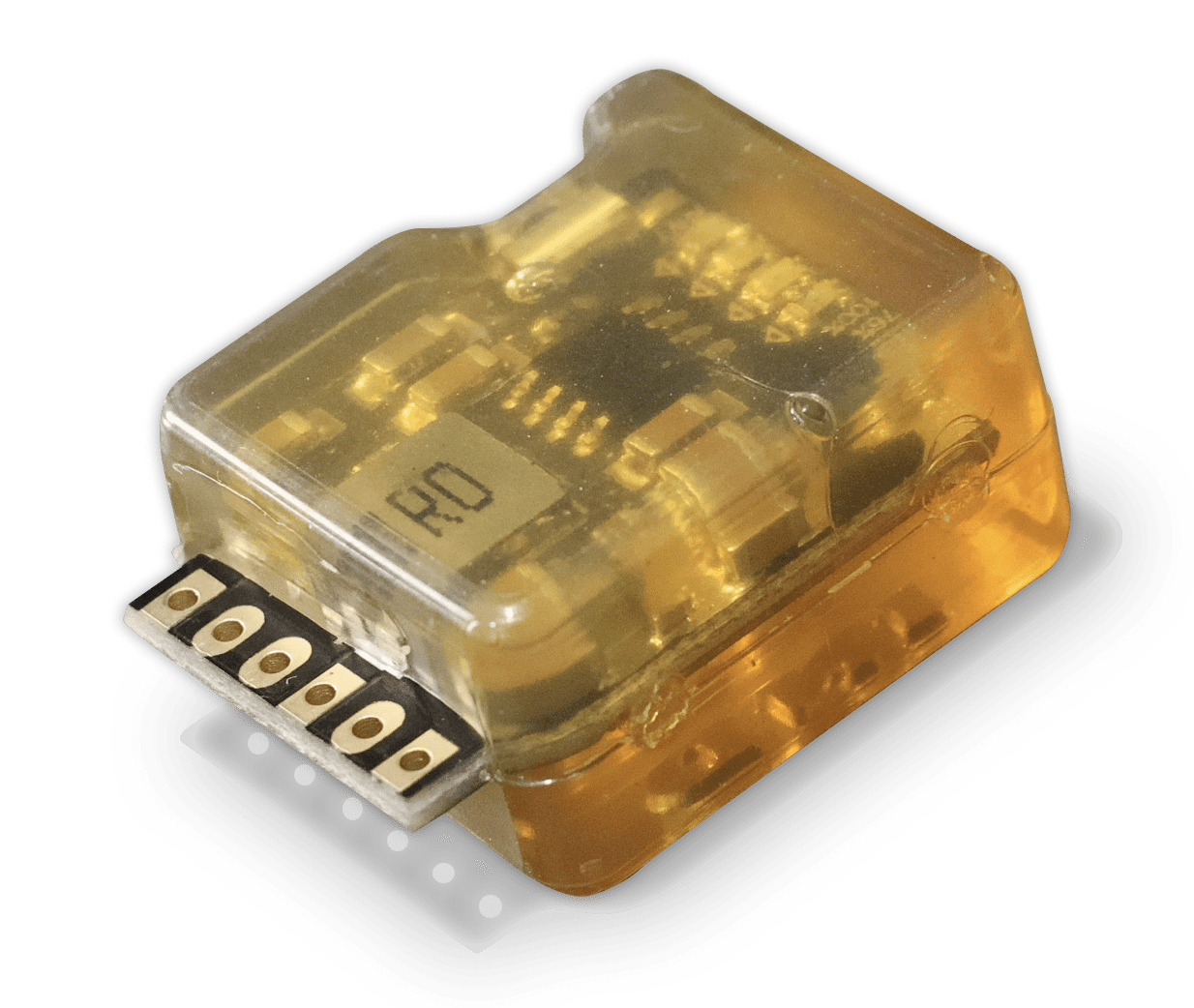

Electronics component overmolding is an encapsulation process that ensures protection against harsh environments and demanding working conditions. Electronic overmolding is extremely useful in a number of demanding applications:

Transportation

Mobile and handheld devices

Military

Industrial

High-performance computing

Aerospace

LGS Overmold has been specialists in electronics overmolding for years, with full in-house mold making and high-volume injection-molding equipment. Our full shop has CNC machines and wire EDMs for contact stamping and forming, and automated contact inspection processes. We guarantee 100% optical inspection capabilities to ensure you get the exact product you ordered.

Molded Multi-Component Modules

Molded multi-component modules are designed for miniaturized, rugged applications. They ensure high-density placement and cost-reduced production processes that yield improved cost and reliability for custom applications.

- Place multiple complex components on a single module

- Ideal for miniaturized, rugged applications in harsh environments

- Affordable method to add security and protection to components

Thermoset molding for bare, die, and passive components:

Why Choose Electronics Overmolding From LGS Overmold?

LGS Overmold has nearly seven decades of experience bringing industry-leading service and innovative technology that solves our customers’ toughest problems.

LGS Overmold specializes in:

Low-pressure electronics overmolding from LGS Overmold is a great option for packaging electronics in any volume range. Injection and demolding times are short, with little labor involved. Our highly refined overmolding process keeps costs down and can be performed for large product ranges and in various colors.

At LGS Overmold, we carefully analyze your project before beginning to choose the best thermoset material which allows us to mold plastic and rubber directly on to PC boards, batteries, LEDs, and antennas. We can perform this at temperatures as low as 90 degrees, which minimizes the stress to electrical components. Further, we do this at pressures as low as 5 PSI, virtually guaranteeing no harm to sensitive electronics components.

You know that you need overmolding to protect sensitive electronics, but you aren’t sure where or how to start? That’s where LGS Overmold comes in. We can provide full consulting and design services to get you started with your important project and help see it through to completion. Our pros have access to all the latest injection molding technologies and techniques and can provide all the help and assistance you need. Count on us for:

- Injection molding design and development

- Prototyping design services

- Help with wall thickness determination

- Help with material shrinkage determination