Low Pressure Injection Molding for Demanding Applications

Custom and standard overmolding to securely protect delicate electronics, done at scale

LGS Overmold delivers high-quality, on-demand injection molding for prototypes and production parts with the quickest turnaround time in the industry. In addition to large-scale production runs, we offer high-quality processing for pilot runs, low-volume production, and bridge tools.

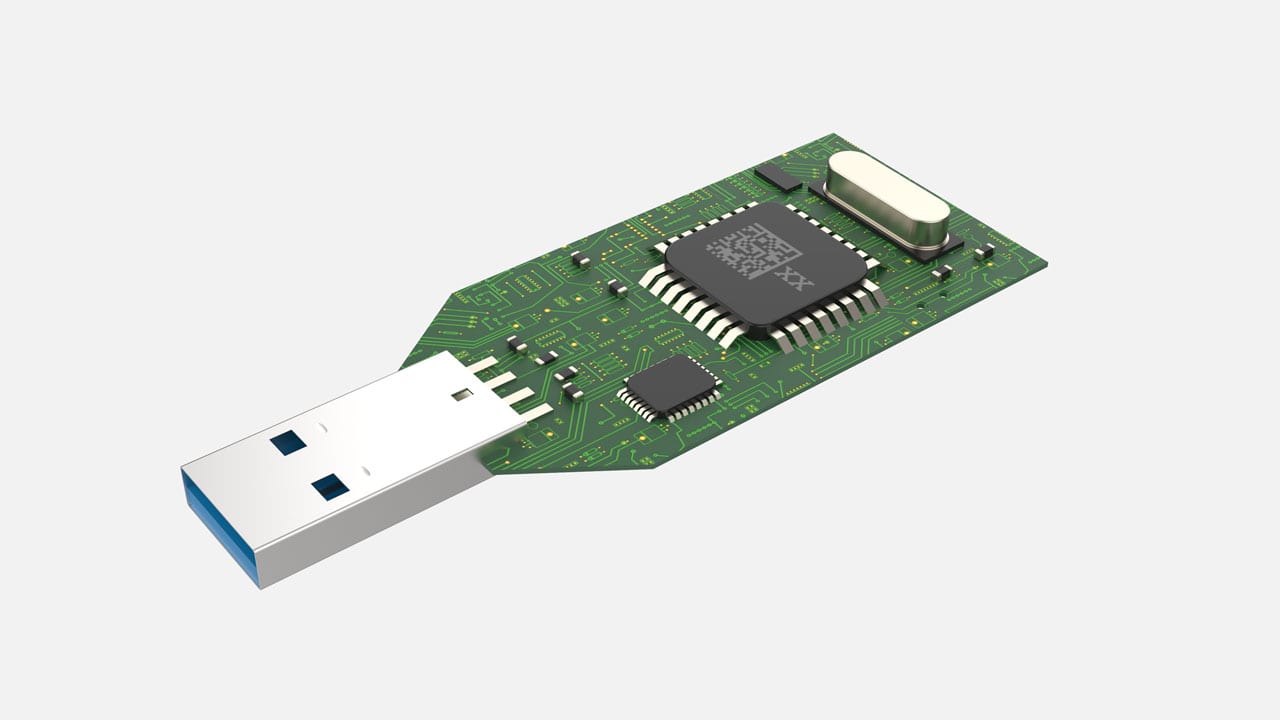

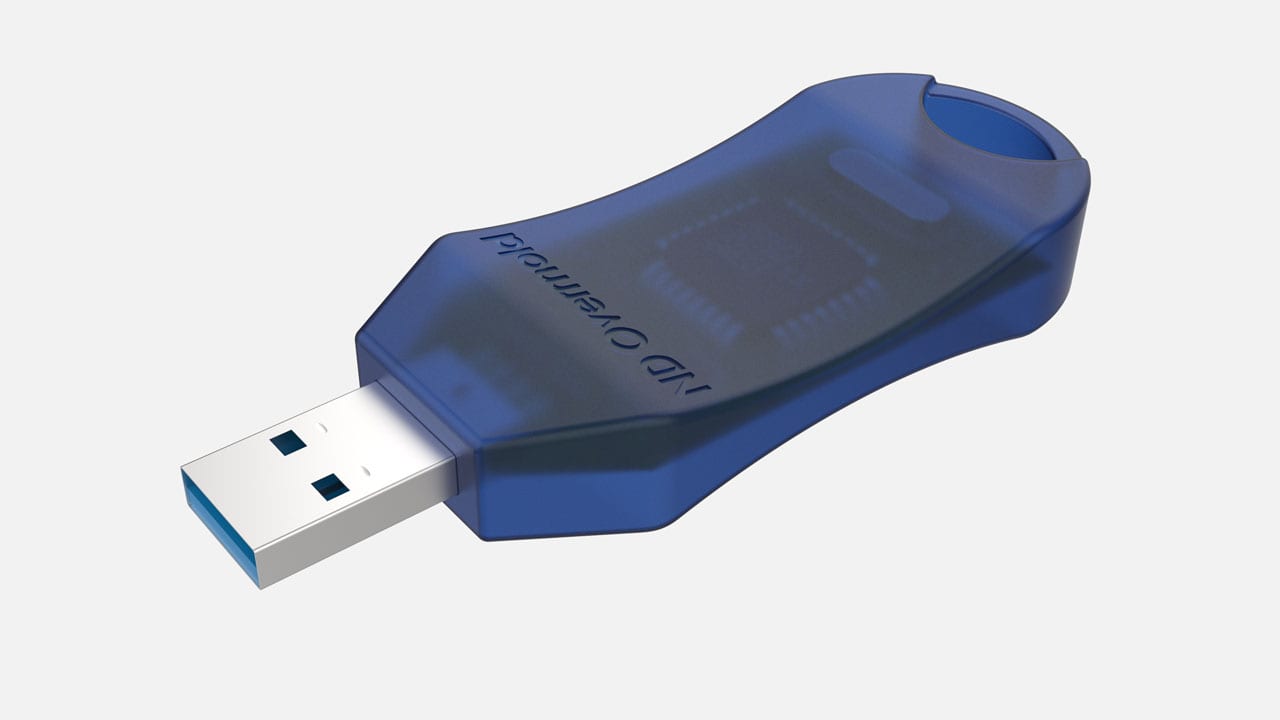

Our overmolding allows you to combine multiple materials into one part, typically using a thermoelastic polymer bonded to a rigid part such as a printed circuit board. Our goal is to provide long-term overmolding solutions, moving clients from rapid prototyping to full-scale production. We have highly trained engineers and project managers on hand to help you with every stage of the low pressure overmolding process, from design to production, no matter your industry.

Not sure if low pressure overmolding is right for your application? Contact us now for a free low pressure overmolding suitability analysis.

Why choose low pressure molding?

Low pressure molding is a refined version of conventional injection molding which uses lower pressure to gently encapsulate delicate electronics assemblies and protect them from harsh environments such as moisture, high temperatures, dust, and chemical exposure.

The low pressure molding is conducted in a press that applies gentle pressure and a molding material to electronics assemblies through a predesigned mold set. Encapsulated parts can typically be moved to final assembly immediately after molding.

LGS Overmold uses time-tested processes to test moldflow simulations prior to low pressure molding. Our low pressure molding materials, which include thermoplastic polyamides and polyolefin hot melt adhesives, are precisely engineered for PCB protection, which lowers cost and improves product performance.

Low pressure molding facilitates cost-effective and sustainable solutions for electronics device manufacturers. Whether your target encapsulation products are PCBs, plugs, connectors, cable bundles, control units, monitors, or sensors, our molding process ensures protected electronics and keeps your products competitive.

Custom overmolding solutions from LGS Overmold

Since 1955, Linear GS has been a leader in developing and manufacturing high-quality materials and processes for demanding fastening and sealing applications for the industrial, automotive, military, and aerospace industries.