Overmold Process

We Are Overmolding Pioneers

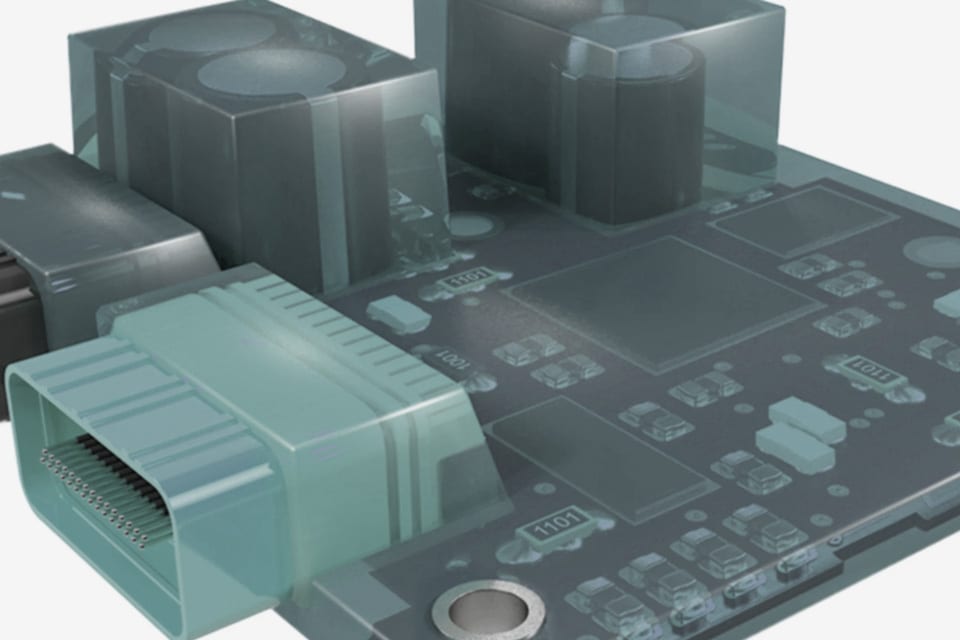

Overmolding encapsulates sensitive electronics and bundles components for a secure, sleek finish that adds usability and aesthetics. The benefits of overmolding include:

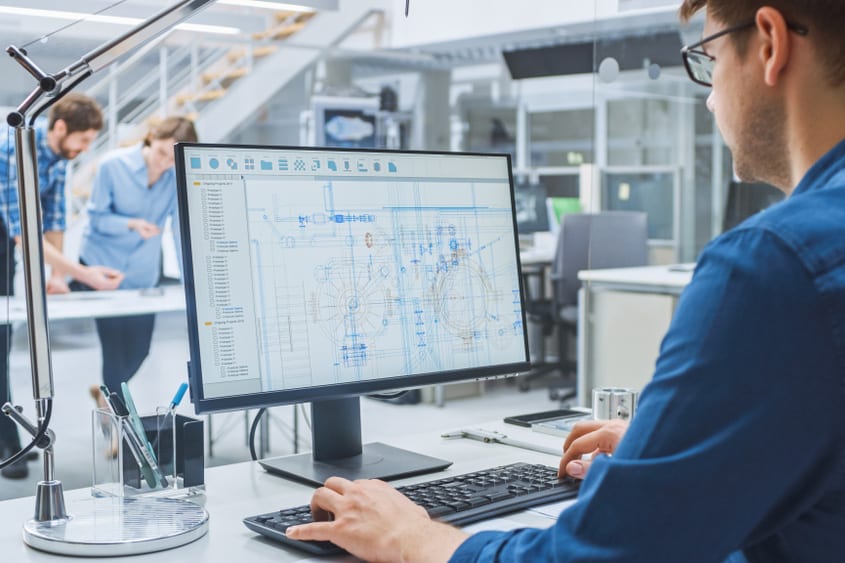

At LGS Overmold, our overmolding process takes place in three simple steps, which means a faster and simpler process, a more cost-effective solution, less handling of electronics, fewer and simpler quality control processes, and lower shipping and handling fees.

How It Works

Overmolding is a multi-step process where two or more components are molded over the top of each other. In a typical overmolding process, two injector units are used to deploy mold into a cavity; after the first injection unit fills the bottom of the mold cavity, the mold opens and rotates 180 degrees, where the second injection then fills the mold cavity over the first mold.

The base component, also known as the substrate, is molded and allowed to cure, with the second layer applied directly on top of it. Materials commonly used in overmolding include ABS, HDPE, PEEK, nylon, polyethylene, silicone, and thermoplastic elastomers.

Overmolding Provides You With Design Flexibility

Besides production benefits like waterproofing and protection against shock and vibration, overmolding provides great design flexibility.

Greater precision

Overmolding can be performed with tight tolerances, meaning designers have more space and flexibility to complete assembled products

More design options

Overmolding permits the use of delicate electronics in places where they otherwise would not function

Skylining

With overmolding, clients can produce finished products with less material and precise volumes, which is known as skylining

Better looking products

Low-pressure molding improves the appearance of end products, and LGS Overmold has the ability to add custom elements such as custom colors and name stamps for unique personalization touches

Better protection for longer life

Overmolding’s quick process and quick cooling means there is minimal heat exposure to components, which results in better overall protection for sensitive electronics

Great Solutions For A Huge Range Of Industries

Overmolding provides solutions for clients in a wide range of industries. Here are some examples:

Consumer goods

You can fiLGS Overmolding processes in sports equipment, children’s games, toothbrushes, plastic containers, cell phone cases, two-tone plastic furniture, plastic housing for GPS units, and thumb drives.

Automotive industry

Overmolding is heavily used in the auto industry, where it is employed for electrical sensors, gears, fasteners, two-tone interior components, dashboards, handles, and knobs.

Medical industry

You will see overmolding in cables, wiring, pacemakers, and endoscopes.

Electrical industry

Overmolding weatherproofs and ensures the safety of electrical components, such as chargers.